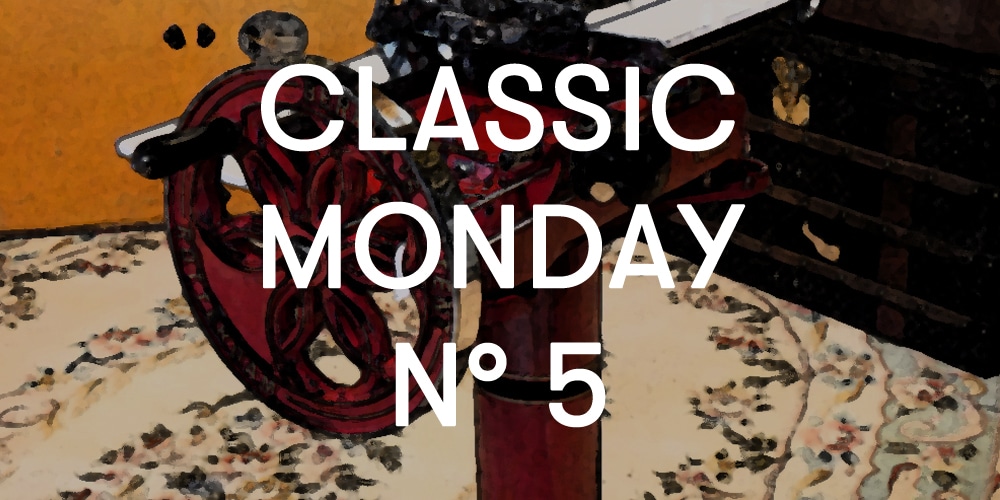

Fifth appointment with Classic Monday: spotlights on the Berkel slicer, which has become a cult object over time.

At the end of the nineteenth century in the city of Rotterdam an enterprising young man with a flair for business scrambled day and night to create a contraption that could facilitate his work as a butcher.

Right from the start he had shown a spirit of initiative and audacity combined with a great passion for mechanics. In those days, butchers cut meat manually and this required considerable precision and meticulousness.

Willhelmus Adrianus Van Berkel dreamed of building an automatic machine that could speed up and simplify his job while ensuring a professional cut.

After countless drawings, projects and prototypes, Van Berkel had the intuition of the concave circular blade and the moving plate.

He built a truly innovative device: turning a crank activated the rotation of the flywheel that transmitted the movement to the blade and the carriage.

The concave blade began to rotate and the carriage, on which the piece of meat to be sliced was fixed, was pushed towards the blade.

Thus was born the first straight-sliding flywheel slicer, baptized as “model A”.

However, the young butcher certainly did not have the necessary means to produce and distribute his new machinery on a large scale.

Van Berkel decided to turn to the owner of a printing house on the verge of bankruptcy and convinced him to go into business with him. Thus it was that in 1989 the company “Van Berkel’s Patents” was born.

In the first year, 76 Berkel Model A machines, three Model B machines and five special Model C machines were produced, a more than decent result at the time.

Van Berkel had to contend with suspicion and resistance to change from butcher shop employees who feared that the slicer could replace them.

He personally approached the butchers and assured that his product would substantially increase sales and even create new jobs.

Thanks to his entrepreneurial spirit and above all to his tenacity, sales of Berkel slicers had a surge and in a few years the company imposed itself on the international scene.

Its strengths were the quality of the materials, the precision of the workmanship and the very high aesthetic value.

In the 120 years of production, Berkel has opened offices all over the world, has improved and modernized its production processes without ever departing from tradition.

Only after World War II was a substantial change introduced thanks to the advent of the electric motor.

This technological improvement allowed the elimination of the flywheel. The new models became less bulky and more manageable, also suitable for domestic use.

Although the original flywheel slicer is no longer used (except as a splendid piece of furniture) it remains a symbol of the perfect balance between elegance and technique.

Suffice it to say that one of the two “Model C” left in the world is part of the prestigious permanent collection of the MoMA in New York (the other is at the Van Berkel Museum in Assisi).

The oldest and rarest models of the Berkel are considered real design objects.

They are highly coveted by collectors and antique dealers, they also constitute a very interesting investment since their value seems to grow from year to year.

In our shop in Cambiago we have two models of these icons: a flaming red 9H and a B100 with gold Liberty decorations. (below the gallery, here info and details)